Pure is Not Pure, Before Repla.

Now REALcycle

Now REALcycle

Now REALcycle

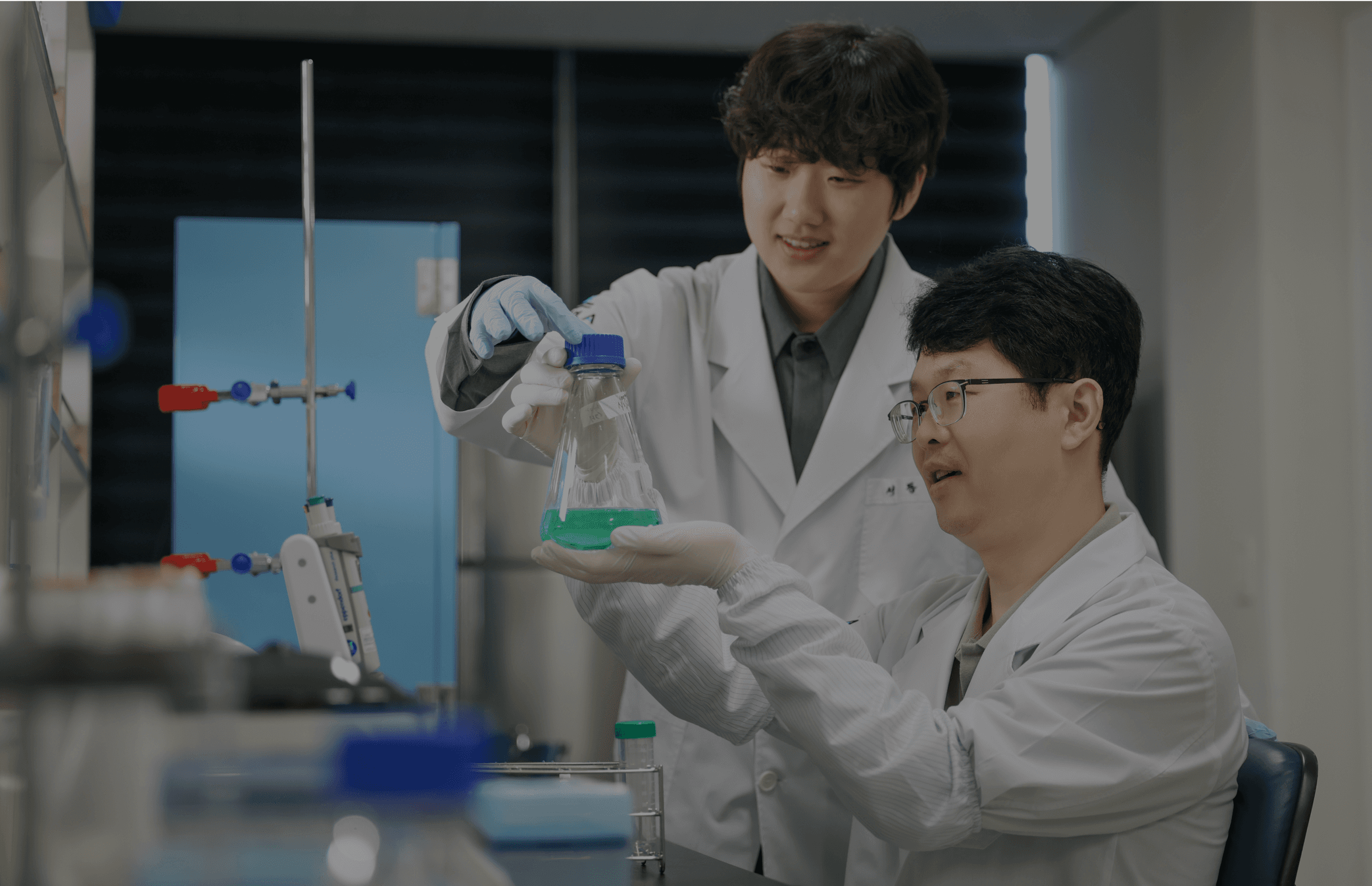

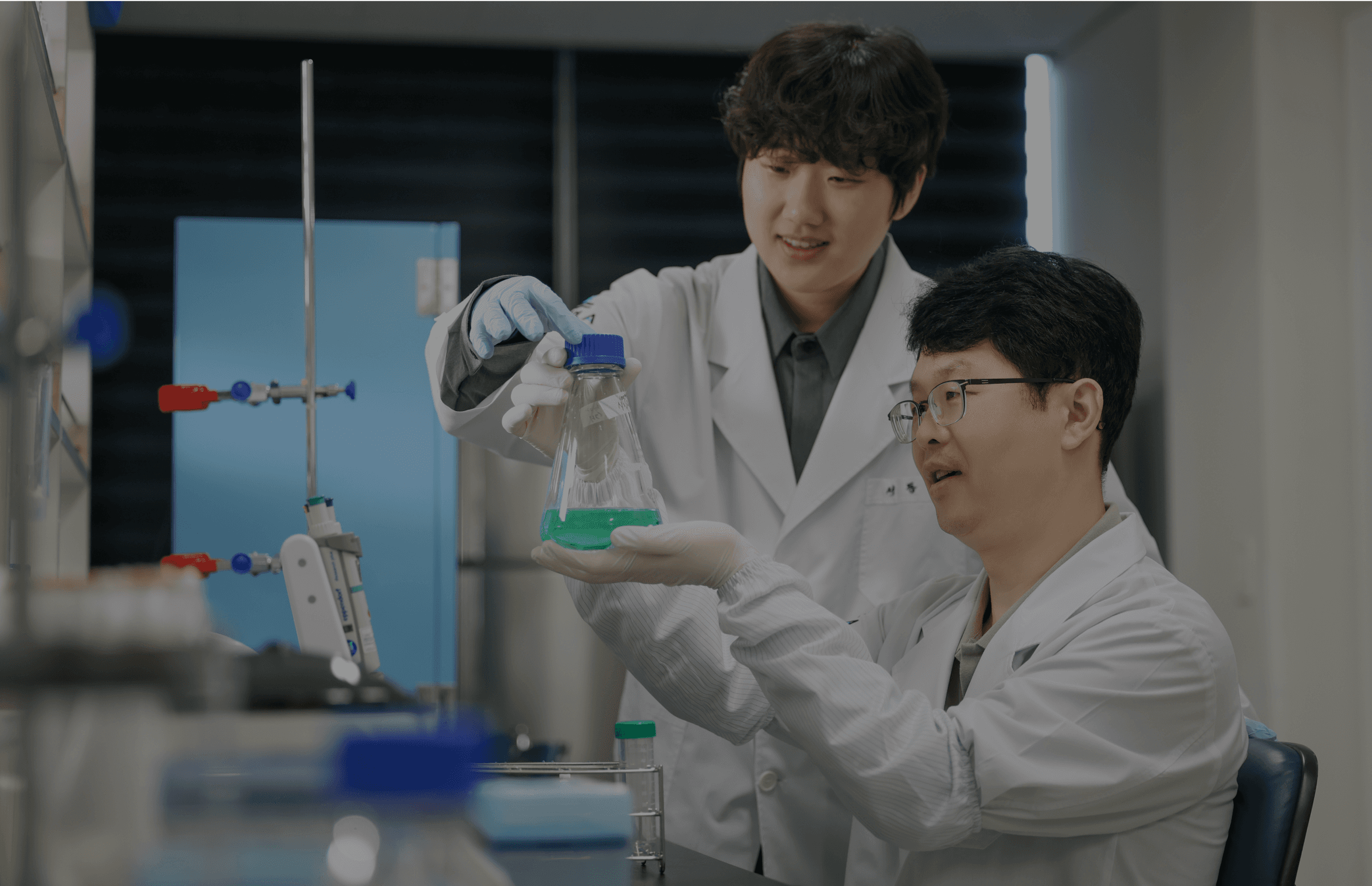

Repla’s bacterial technology selectively degrades all types of plastics except PP,

breaking down the carbon chain structure through enzyme activity.

Our bacterial technology selectively degrades all types of plastics except PP, breaking down the carbon chain structure through enzyme activity.

Mission

Global Plastic Recycling Rate

9% → 30%

Repla aims to increasing the Global Plastic Recycling Rate from 9% to 30%, opening a new era of ‘True Eco-Friendly Recycling’.

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Business Model

High-Quality Recycled Raw Materials

1.5x Price Increase

Repla removes hard-to-process impurities, enabling high-value recycling for automotive and electronics.

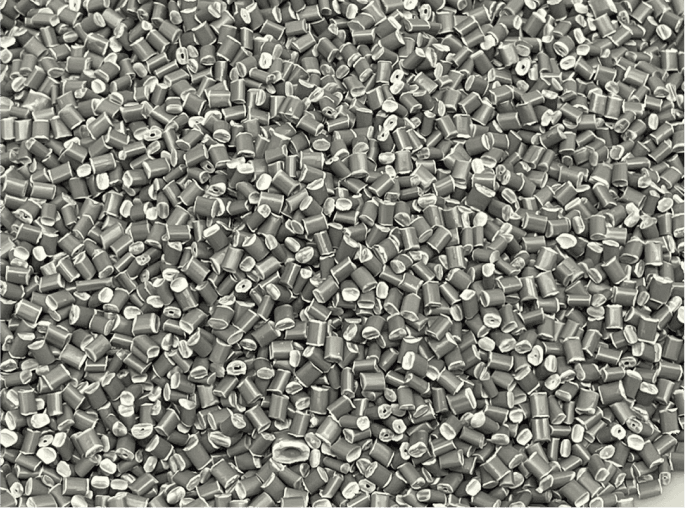

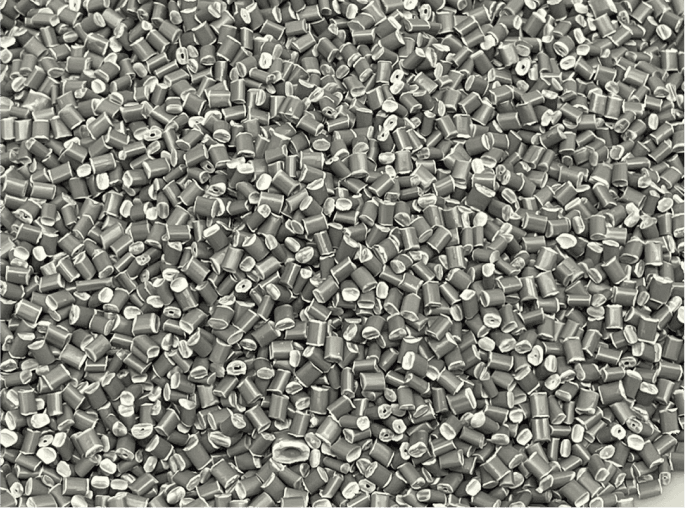

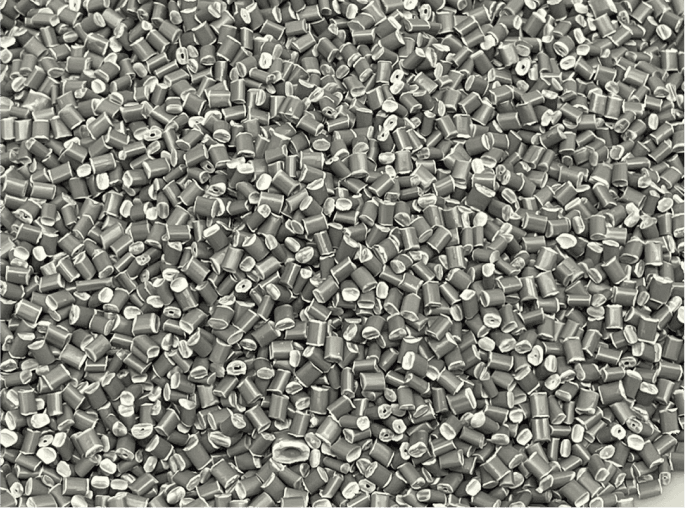

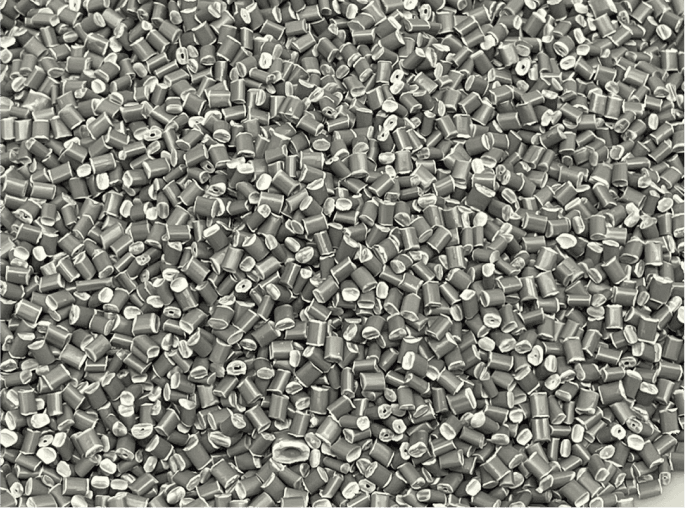

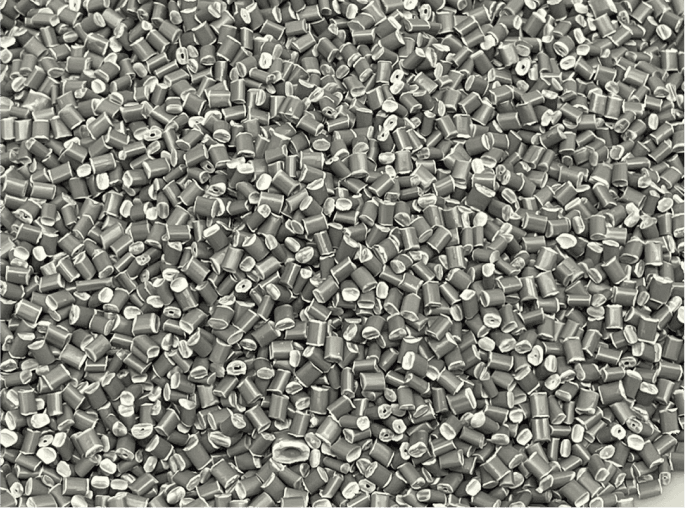

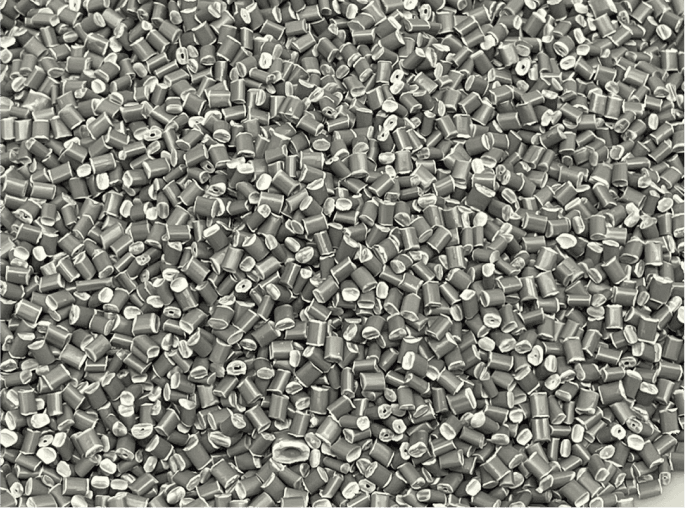

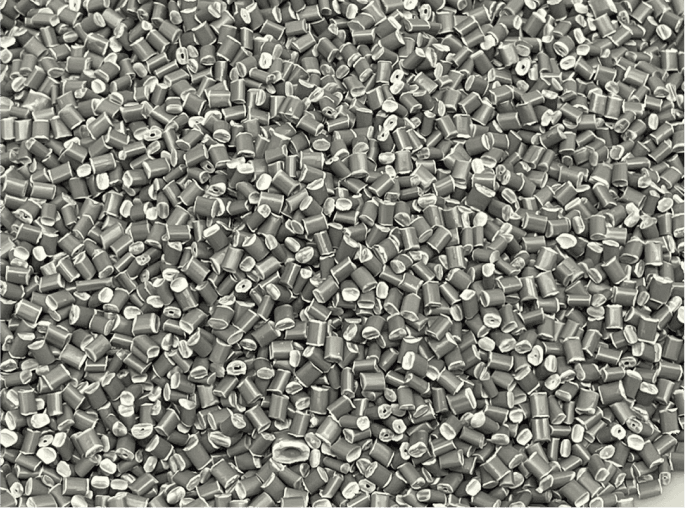

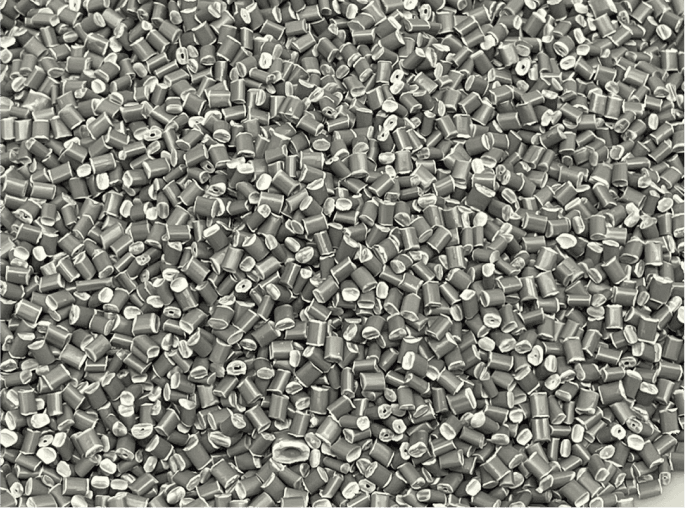

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

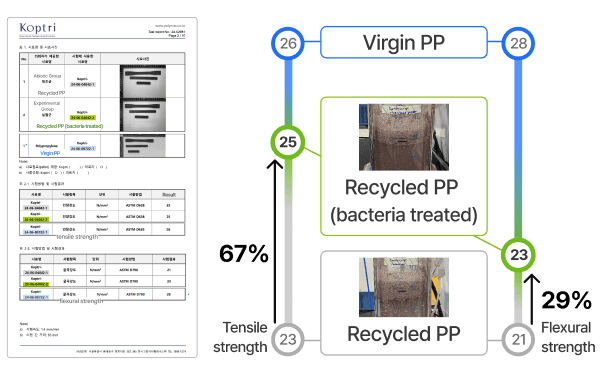

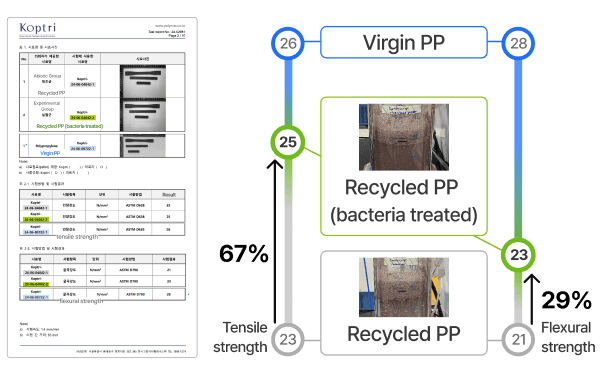

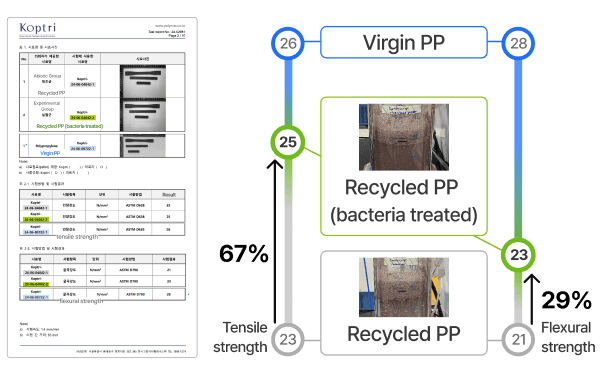

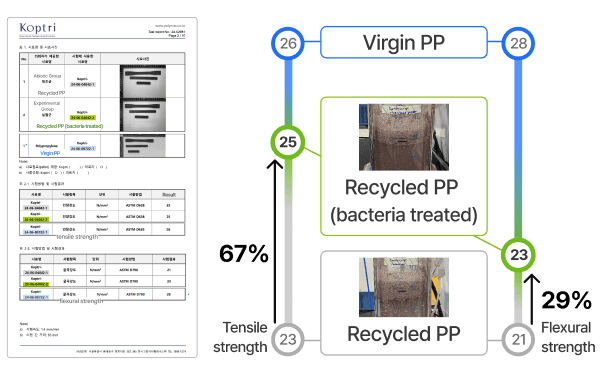

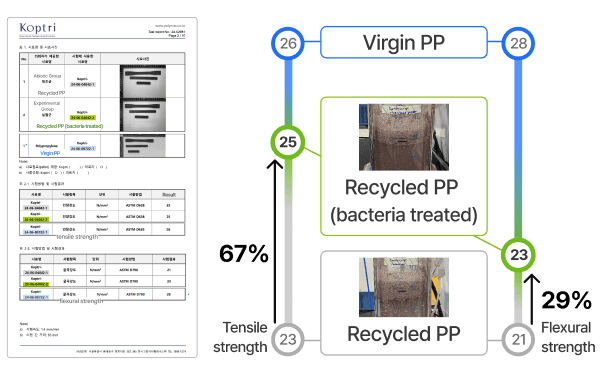

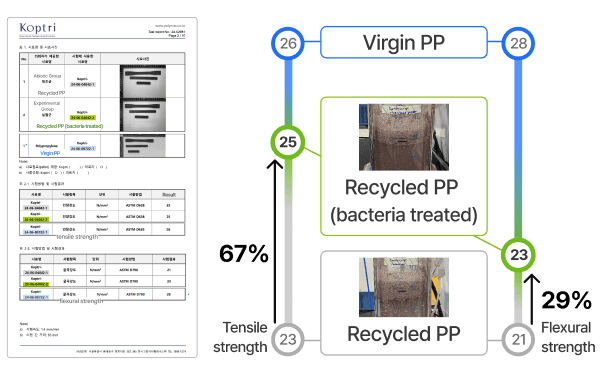

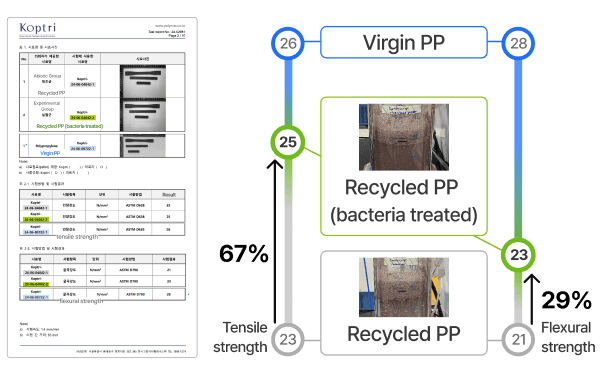

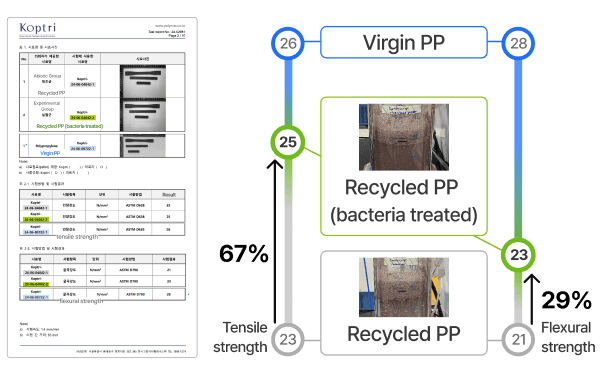

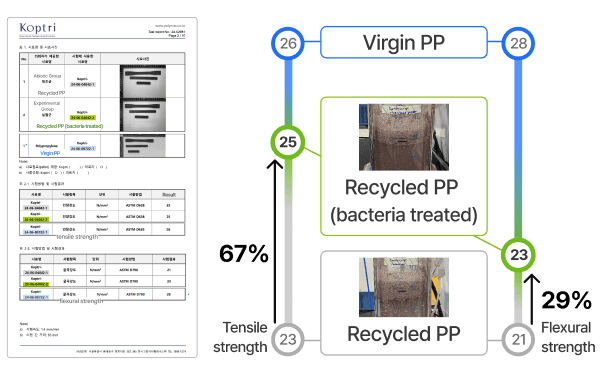

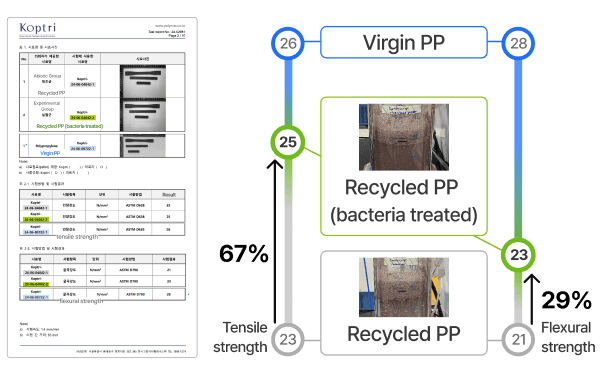

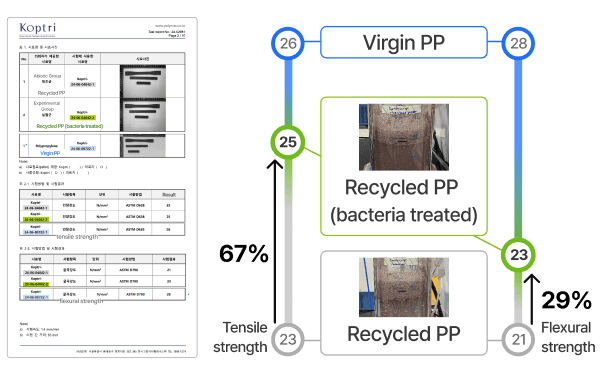

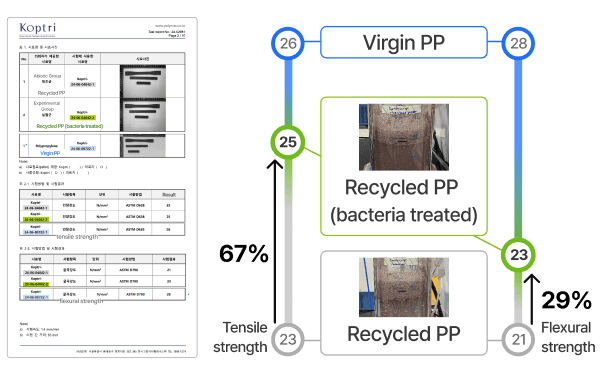

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

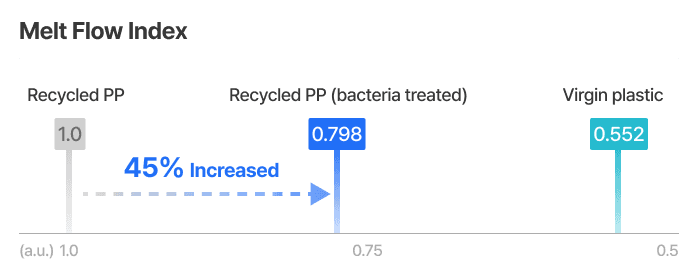

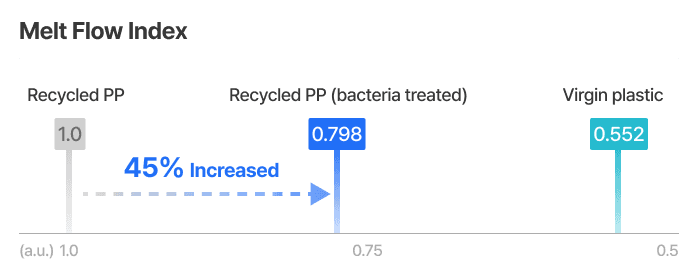

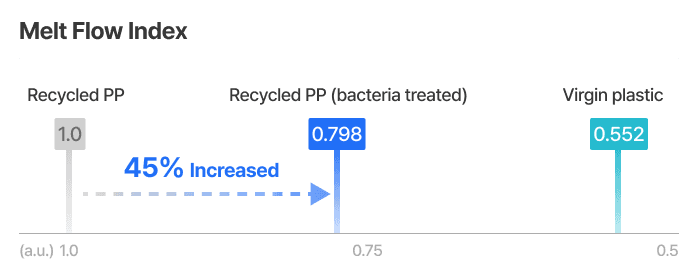

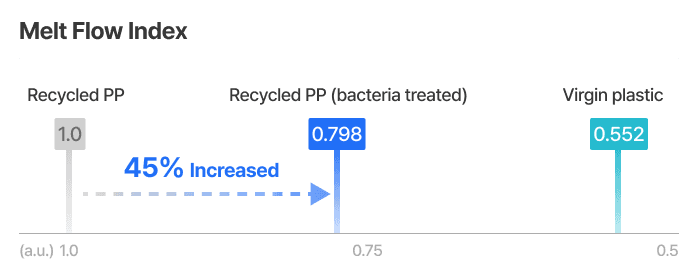

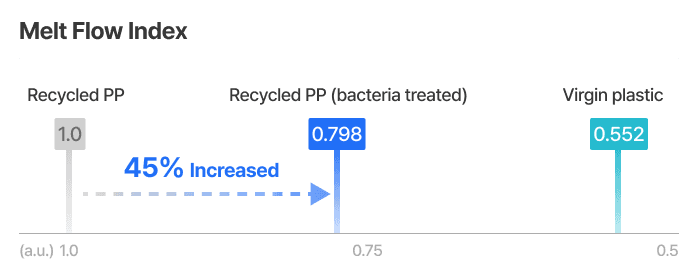

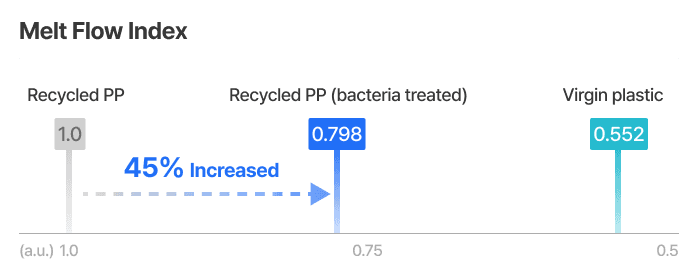

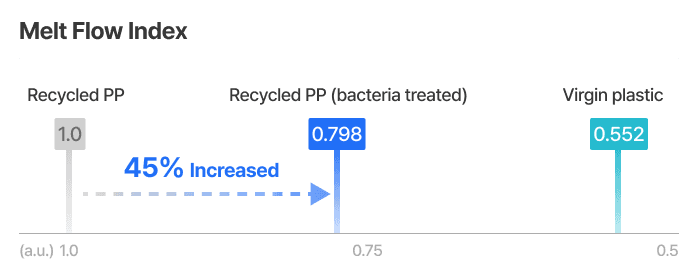

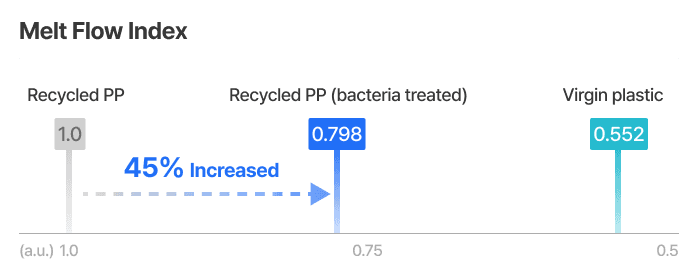

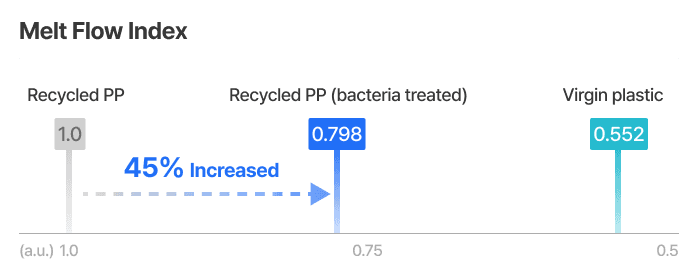

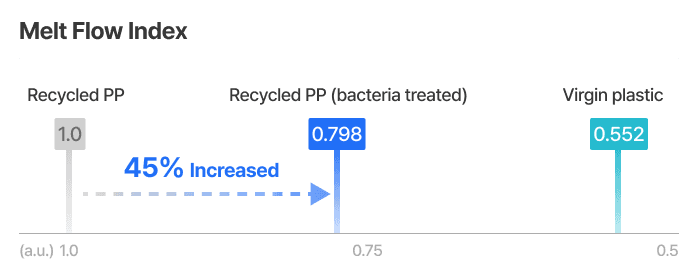

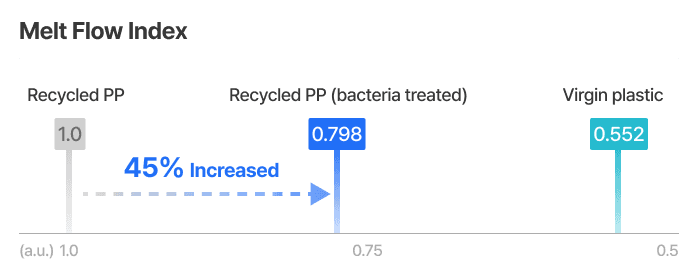

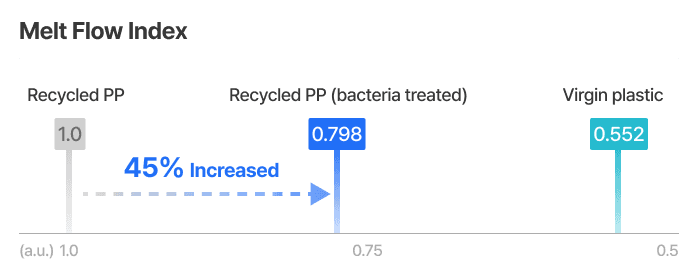

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

Solution

Patented Bacteria Technology - Bacteria

Bacteria

Breaks carbon chains in olefin plastics through enzyme action to selectively degrade unnecessary plastics and enhance the purity of single-material plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving Recycled Material Quality - Biotank

Biotank

Enhances material quality by adding a biotank to existing processes with just 25㎡ of spaceanywhere in the world.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources - Repla Factory

Repla Factory

Collects plastics destined for incineration andconverts them into resources through aproprietary bacteria process

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology - Bacteria

Bacteria

Breaks carbon chains in olefin plastics through enzyme action to selectively degrade unnecessary plastics and enhance the purity of single-material plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving Recycled Material Quality - Biotank

Biotank

Enhances material quality by adding a biotank to existing processes with just 25㎡ of spaceanywhere in the world.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources - Repla Factory

Repla Factory

Collects plastics destined for incineration andconverts them into resources through aproprietary bacteria process

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology - Bacteria

Bacteria

Breaks carbon chains in olefin plastics through enzyme action to selectively degrade unnecessary plastics and enhance the purity of single-material plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving Recycled Material Quality - Biotank

Biotank

Enhances material quality by adding a biotank to existing processes with just 25㎡ of spaceanywhere in the world.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources - Repla Factory

Repla Factory

Collects plastics destined for incineration andconverts them into resources through aproprietary bacteria process

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology - Bacteria

Bacteria

Breaks carbon chains in olefin plastics through enzyme action to selectively degrade unnecessary plastics and enhance the purity of single-material plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving Recycled Material Quality - Biotank

Biotank

Enhances material quality by adding a biotank to existing processes with just 25㎡ of spaceanywhere in the world.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources - Repla Factory

Repla Factory

Collects plastics destined for incineration andconverts them into resources through aproprietary bacteria process

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Mission

Global Plastic Recycling Rate

9% → 30%

Raising the Global Plastic Recycling Rate from 9% to 30%,

Opening a New Era of True Eco-Friendly Recycling.

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Landfilling / Disposal

79%

Incineration

12%

Recycle

9%

321,230,000 ton

Amount of plastic waste discarded worldwide annually Global plastic waste generation

2022 OECD, Global Plastics Outlook

353,000,000 ton

Global Plastic Waste Generation

2022 OECD, Global Plastics Outlook

Vision

Business Model

1.5x Price Increase

Removes hard-to-process impurities, enabling high-value recycling for automotive and electronics.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

High Purity rPP

Repla’s bacteria-treated recycled PP pellets

©2024 REPLA Inc.

Tensile and Flexural Strength

Strength increased by 67% and 29%, respectively

©2024 REPLA Inc.

Enhanced MI Index

20.2% improvement compared to conventional recycled plastics

©2024 REPLA Inc.

Solution

Patented Bacteria Technology

Bacteria

Breaking Carbon Chains in Olefin Plastics through Enzyme Action to Selectively Degrade Unnecessary Plastics, Enhancing the Purity of Single-Material Plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving

Recycled Material QualityBiotank

Enhance Material Quality by Adding a BioTank to Existing Processes with Just 25㎡ of Space, Anywhere in the World.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources

Repla Factory

Collecting Plastics Destined for Incineration and Converting Them into Resources Through a Proprietary Bacteria Process.

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology

Bacteria

Breaking Carbon Chains in Olefin Plastics through Enzyme Action to Selectively Degrade Unnecessary Plastics, Enhancing the Purity of Single-Material Plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving

Recycled Material QualityBiotank

Enhance Material Quality by Adding a BioTank to Existing Processes with Just 25㎡ of Space, Anywhere in the World.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources

Repla Factory

Collecting Plastics Destined for Incineration and Converting Them into Resources Through a Proprietary Bacteria Process.

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology

Bacteria

Breaking Carbon Chains in Olefin Plastics through Enzyme Action to Selectively Degrade Unnecessary Plastics, Enhancing the Purity of Single-Material Plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving

Recycled Material QualityBiotank

Enhance Material Quality by Adding a BioTank to Existing Processes with Just 25㎡ of Space, Anywhere in the World.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources

Repla Factory

Collecting Plastics Destined for Incineration and Converting Them into Resources Through a Proprietary Bacteria Process.

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Patented Bacteria Technology

Bacteria

Breaking Carbon Chains in Olefin Plastics through Enzyme Action to Selectively Degrade Unnecessary Plastics, Enhancing the Purity of Single-Material Plastics.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Selective Degrading

Repla’s Proprietary Cultivation

©2024 REPLA Inc.

Bacteria System for Improving

Recycled Material QualityBiotank

Enhance Material Quality by Adding a BioTank to Existing Processes with Just 25㎡ of Space, Anywhere in the World.

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Eco-Friendly System

Reuses culture medium without wastewater treatment

©2024 REPLA Inc.

Installation without Location Constraints

Requires only 25㎡ of space

Maintaining Existing Processes

Integrates seamlessly at the final stage of existing recycling processes

Turning Waste into Resources

Repla Factory

Collecting Plastics Destined for Incineration and Converting Them into Resources Through a Proprietary Bacteria Process.

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

Purchasing Discarded

Plastics WastesTransforms more waste into valuable resources

REALcycle with Repa, the next generation of recycling

REALCYCLE

REAL Sustainability

minimal requirement constraints

REAL High-Quality

applicable for extended uses

REAL High-Value

real high purity eco-friendly recycling

REALcycle with Repa,

the next generation of recycling

REALCYCLE

REAL Sustainability

minimal requirement constraints

REAL High-Quality

applicable for extended uses

REAL High-Value

real high purity eco-friendly recycling

News

Repla at RETECH 2024: Connecting with Industry Experts in Plastic Recycling

Vision for a Sustainable Future, at RETECH 2024

(KOR Sub) Vision for a Sustainable Future, at RETECH 2024

REALcycle with Repa,

the next generation of recycling

REALCYCLE

REAL Sustainability

minimal requirement constraints

REAL High-Quality

applicable for extended uses

REAL High-Value

real high purity eco-friendly recycling

REALcycle with Repa,

the next generation of recycling

REALCYCLE

REAL Sustainability

minimal requirement constraints

REAL High-Quality

applicable for extended uses

REAL High-Value

real high purity eco-friendly recycling

Repla begins

new plastic recycling, REALCYCLE

237 Yeongtong-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do, Republic of Korea.

Copyright (C) REPLA. All Rights Reserved.

Repla begins new recycling, REALCYCLE

237 Yeongtong-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do, Republic of Korea.

Copyright (C) REPLA. All Rights Reserved.

Repla begins

new plastic recycling, REALCYCLE

237 Yeongtong-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do, Republic of Korea.

Copyright (C) REPLA. All Rights Reserved.